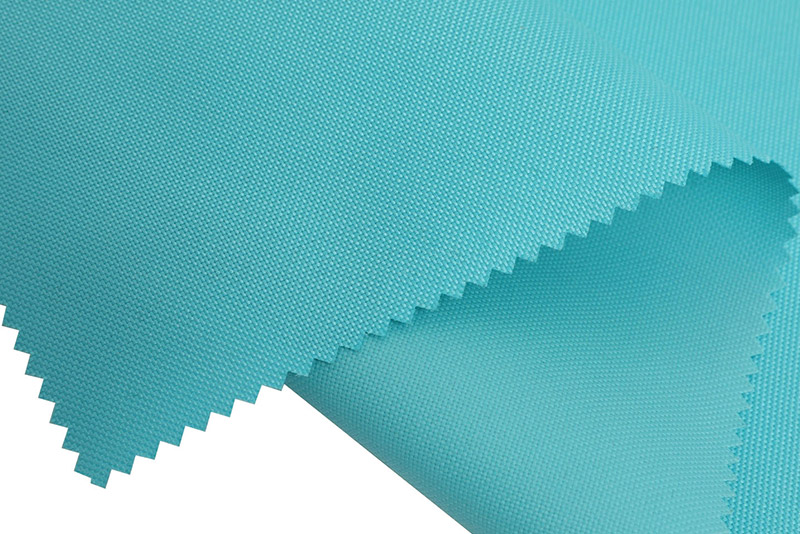

I-polyester fiber, eyaziwa ngokuba yi "polyester".Yifiber eyenziweyo efunyenwe ngokujikeleza i-polyester efunyenwe nge-polycondensation ye-organic dibasic acid kunye ne-dihydric alcohol.Yikhompawundi yepolymer kwaye lolona didi lukhulu lweentsinga zokwenziwa ngoku.Amalaphu e-polyester asetyenziswa kakhulu kwishishini lokulungelelanisa imithwalo, kwaye amalaphu e-polyester asetyenziswa kwiimveliso ezininzi zeengxowa.Ngoko ke, ukuba ubona "i-polyester fiber" ebhaliweyo kwinkcazo yezinto eziphathekayo kwithegi ye-backpack kwixesha elizayo, i-backpack yenziwe ngelaphu le-polyester.

Ilaphu lepolyester lelinye lamalaphu aqhelekileyo obhaka.Inokumelana nokushwabana okugqwesileyo, ukugcinwa kwemilo, ukomelela okuphezulu kunye nekhono lokubuyisela i-elastic, ukuxhathisa imibimbi, akukho ironing, iinwele ezinganamatheli kunye nezinye izibonelelo.

1. I-elasticity yelaphu le-polyester ilungile

Ilaphu lePolyester linamandla aphezulu kunye nekhono lokubuyisela i-elastic, kwaye linokumelana nokushwabana okuhle kunye nokugcinwa kwemilo.Isetyenziselwa ukwenza oobhaka.Ubhaka ogqityiweyo womelele kwaye awugugi.Ilaphu aliguquguquki ngokulula phantsi kwesenzo samandla angaphandle, lixhathise kakhulu imibimbi, kwaye ngokusisiseko ayifuni uku-ayina., Uyilo lomzimba wepakethi luya kuba tyaba, lune-dimensional emithathu kunye nesitayile.Ngaphantsi kokusetyenziswa okuqhelekileyo, iipakethi ezenziwe ngamalaphu e-polyester zihlala zihlala ziqinile kwaye azikhubazeki lula.

2. Ukumelana nokukhanya okulungileyo

Ukukhanya okukhanyayo kukwesibini kuphela kwi-acrylic (uboya bokufakelwa).Ukukhanya okukhanyayo kwelaphu le-polyester kungcono kune-fiber ye-acrylic, kwaye ukukhawuleza kwayo ukukhanya kungcono kunokwelaphu le-fiber yendalo.Ngokukodwa ukukhanya okukhawulezayo emva kweglasi kuhle kakhulu, phantse ngokuhambelana ne-acrylic.Iimveliso zeBackpack ezenziwe ngamalaphu e-polyester azihambelani nemozulu, i-embrittlement kunye ne-fracture xa isetyenziswe kwiimeko zangaphandle.

.

3. Ukudaya kakubi

Nangona ilaphu lepolyester lidayi kakubi, linombala okhawulezayo.Emva kokuba idayiwe ngempumelelo, ayiyi kuphelelwa lula, kwaye ayiyi kuphelelwa lula ngexesha lokuhlanjwa.Yenziwe kwimveliso ye-backpack, kwaye ilaphu alilula ukucima emva kokusetyenziswa kwexesha elide, kwaye umphumo wokugcina umbala ulungile kakhulu.

.

4. I-hygroscopicity engalunganga

I-hygroscopicity ye-polyester ibuthathaka kunaleyo yenayiloni, ngoko ke ukugqithiswa komoya akufani nokwenayiloni, kodwa kanye ngenxa ye-hygroscopicity engafanelekanga yamalaphu e-polyester ukuba amalaphu e-polyester kulula ukuwomisa emva kokuhlanjwa, kunye nokomelela kwelaphu. phantse iyancipha, ngoko akukho lula ukukhubaza.Iimveliso zikabhaka ezenziweyo zisebenzisa indlela echanekileyo yokuhlamba, kwaye ngokuqhelekileyo azifaneli ukuguquka ngenxa yokuhlamba.

.

5. I-thermoplasticity elungileyo kunye nokunganyangeki okubi

Ngenxa yomgangatho ogudileyo wepolyester kunye nolungiselelo olusondeleyo lweemolekyuli zangaphakathi, i-polyester lilaphu elinokumelana nobushushu phakathi kwamalaphu e-synthetic fiber kwaye ineempawu ze-thermoplastic.Ngoko ke, iipakethi zelaphu le-polyester kufuneka zizame ukunqanda ukudibanisa ne-cigarette butts, iintlantsi, njl.

.

Kwinkqubo yokuluka amalaphu e-polyester, ngenxa yobunzima obuhlukeneyo beentsinga ezisetyenzisiweyo, zinokwahlulwa zibe ziintlobo ezahlukeneyo zenkcazo.Iimpawu zeelaphu ze-polyester zibonakaliswa ngokuqhelekileyo ngokuthi "ubuhle (D)", kwaye ubuncinci bubizwa ngokuba yi-denier, oko kukuthi, i-denier.Inani elikhulu le-D, ukutyeba kwelaphu, ubukhulu begram ubunzima, kwaye kungcono ukuxhathisa ukunxiba.Umzekelo, i-150D, i-210D, i-300D, i-600D, i-1000D, i-1680D, njl. njl. ngokuqhelekileyo zisetyenziselwa i-polyester imigqaliselo yelaphu, njenge-150D, i-210D kunye namanye amalaphu amancinci amancinci, amaninzi asetyenziselwa ukwenza i-backpack linings, i-300D engaphezulu kwe-300D. , isiseko Isetyenziswa njengento ephambili ye-backpack.

Ixesha lokuposa: Sep-24-2022